Since there seems to be some interplay between the SPI overlap mode and the Sigma Delta, I decided to disable the SPI RAM code to see if I can get the Voltage Boost working without crashes. I used the // comment to make nullify the lines of code pertinent to the HSPI overlap mode. Most IDEs let you select multiple lines and type CTRL-/ to comment out a block of code, and it toggles between commented and uncommented.

Note: IDE means Integrated Development Environment. Some IDEs are very advanced and checks if your code will compile while your are typing it in. Others are just a simple editor with an integrated programmer/compiler. In my case, I am using a program called Eclipse as my IDE. It is very powerful as a code editor and I could automate compiling and uploading with it, but I have taken an easier path of making a few special shell files to automate the compiling/uploading process.

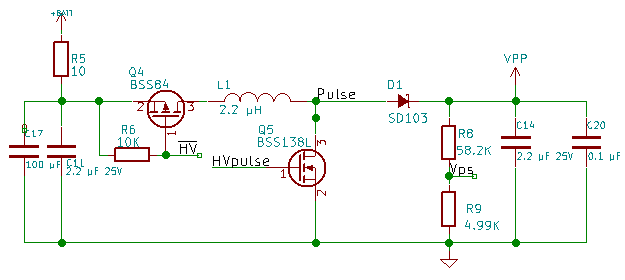

After commenting out the HSPI overlap code, I verified It would compile and run. It compiled and ran. Good so far. Next I started re-enabling the voltage boost circuit a little at a time. First, I turned of the FET allowing the current to flow into the boost circuit. This is done by pulling GPIO16 low. I did this by uncommenting two lines at the beginning of serial_init. (I also made a quick edit to a comment that was erroneous) I saved that and tried again. I measured Vpp at 2.75V.

The Sigma Delta Generator was set to a prescaler of 1 and duty of 0 from the last tests I had done. Next I started changing the prescaler to see if the behavior has changed. 98 .. 99 .. 100 rst cause:2(Failure) Next I thought “maybe it’s the WiFi Modem”, So I disabled the modem. I added the following three lines to the end of user_init()

wifi_set_opmode(NULL_MODE);

wifi_fpm_set_sleep_type (MODEM_SLEEP_T);

wifi_fpm_open(); // force modem to sleep

98 .. 99.. 100 rst cause:2 (another failure)

Next I set GPIO16 to 1 in user_init() and commented it’s configuration out in seial_init(). Same result. Next I re-enabled system_set_os_print(). Maybe it’ll give me some useful message. No new messages came across the terminal emulator. I commented out the wifi_set_event_handler_cb() line. Still fails at 100.

So user_init() now:

sets the cpu frequency,

configures all the ports, including making sure all pins are disconnected from the sigma delta,

Initializes serial communications,

Initializes the Sigma Delta,

and disables the Modem.

cpu frequency is a system call,

Ports are just register writes,

serial communications are kinda of complex,

Sigma Delta is Just register writes,

and disabling the modem uses system calls.

This points to something in the serial communications.

Looking through the uart code, I noticed the ICACHE_FLASH_ATTR for uart_recvTask(); This is an ISR (interrupt service routine), and they shouldn’t reside in Flash, they should always be in ram. I commented out the line and tried again. Again, same failure. I decided to sleep on it.

Moving forward, I continued to look at the serial communications code. I decided to remove all the menu display code and just display the prescaler value with each keypress. While making this change, I noticed that I had made a string buffer called outBuf of 32 bytes long. I used outBuf to format the Sigma Delta data before sending it out the serial port. I counted it’s length, with a Duty of 0 and a Prescaler of 100 the terminating null character would be in position 35 of the buffer(That’s a buffer overrun). I quickly shortened the string to leave the rest of the code intact and tried again. And that solved it.

I re-enabled the menu.

Still working.

I re-enabled the boost voltage source.

Still working

Set the duty to 51(20%).

It is still working and I measured 2.72V at Vpp (2.72V doesn’t make sense)

Turns out I had both the Vpp drive and grounding transistors turned on causing the low voltage. I set GPIO5 low and measured again with prescaler set to 4 and duty set to 102, I measured 22V on Vpp. Success!!!(little victory dance there)

I put a //TODO comment in my code to check everywhere I am using a string buffer for possibility of buffer overruns.

Putting a comment that starts with //TODO automatically adds it to a task list in the IDE. I can then go to the tasks list to see these notes. I now have stable but highly crippled code. I have uploaded the current state of the code to Github, click the firmware link in the right column to go get it or look at it.

When you are debugging do you have a technique that works especially well for you. Do you have a technique for finding buffer overruns? I would love to hear about your experiences.