Last week, the voltage boost circuit would barely get above 12 volts. This would work for most devices but I had set my goal at around 20v. I rechecked datasheets to verify I wasn’t operating out of specification.

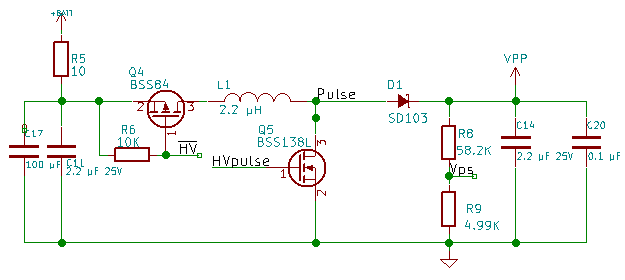

Diode D1: The voltage across this diode is really close to 12V when Q5 is on and C14 is charged. From the datasheet, the reverse breakdown voltage(Vr) for and SD103 is 40 V. This is a fast switching Schottky diode. This is probably not my problem.

FET Q5: The voltage across the drain to source will also reach around 13 Volts when in the off phase of the pulse stream. The drain to source breakdown voltage is 50 V. This transistor can switch fast enough even at 80MHz. This is probably not my problem.

Resistor R5: I chose to use 100 Ohms when I populated the PCB. I am definitely seeing a voltage drop at C17 when driving to around 12 Volts. If this is the problem, I will not even be able to get to 12V when running on the lithium cell. I think this is causing the problem.

To test this, I decided to change the resistor to 47 Ohms and redo my testing.

I tested with a prescaler of 0, 1, 2, and 4. With a prescaler of 4 I got 20 volts with the duty set to 51.

Analysis and testing revealed that the filter resistor R5 was too much resistance. By changing it’s value to 47 Ohms, I was able to get the circuit operating the way I wanted.

I made no changes to the software other than changing the prescaler. For this firmware, that is a value that I expect to be played with, so no firmware upload this week. I did change the value of resistor R5 to 47 Ohms. So I uploaded a new version of the hardware to GitHub.

I would like to see smaller steps between voltages, I am thinking of changing the inductor to a smaller value to improve efficiency and control. I am not sure this works, but it might be worth a try.

I am still working in an area of electronics I don’t understand very well. This is the first time for me to design a switching voltage boost circuit. Do you have any suggestions of how to do it better? How about stories about your own experience with switching power supplies.