With the design review and testing done, it is time to update the layout. I started by doing a Design rules check on the schematic. I got 3 errors, two were passives connected to inputs. I changed the analog input of U10 Pin 3 to a passive pin. This is not a problem, but might be in other circuits. The third indicated two power outputs were connected together. The CH340G has a 3 volt pin that operates as either a power input (3.3v operation), or as an output (5v Operation), I went in and edited it to be a bidirectional pin. It still gave me a warning, but it’s acceptable.

Design rule warnings and errors are important, for each one, I will check to make sure it doesn’t represent a real problem and try to fix it.

I then ran CvPCB to confirm all devices have an assigned footprint. I had made some changes that means a few new components, and footprints. I got all the parts assigned and saved them. then saved the schematic sheet. I then ran a netlist. I opened the layout design, and imported the new netlist… it gave me an error. It couldn’t find the library Housings_SOT-23_SOT-143_TSOT-6. The library name had changed, I went back into CvPCB and found the TO_SOT_Packages_SMD library that had the SOT23 footprint that I needed for all of my transistors. After making reassigning the footprints, I re-saved CvPCB and the schematic file, then generated a new netlist.

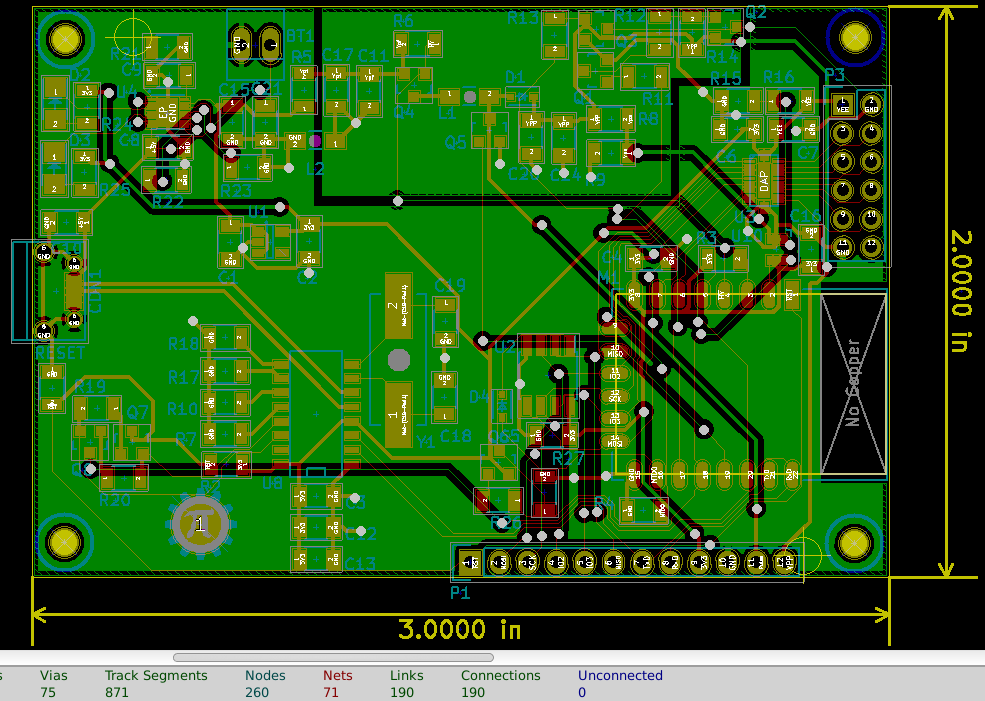

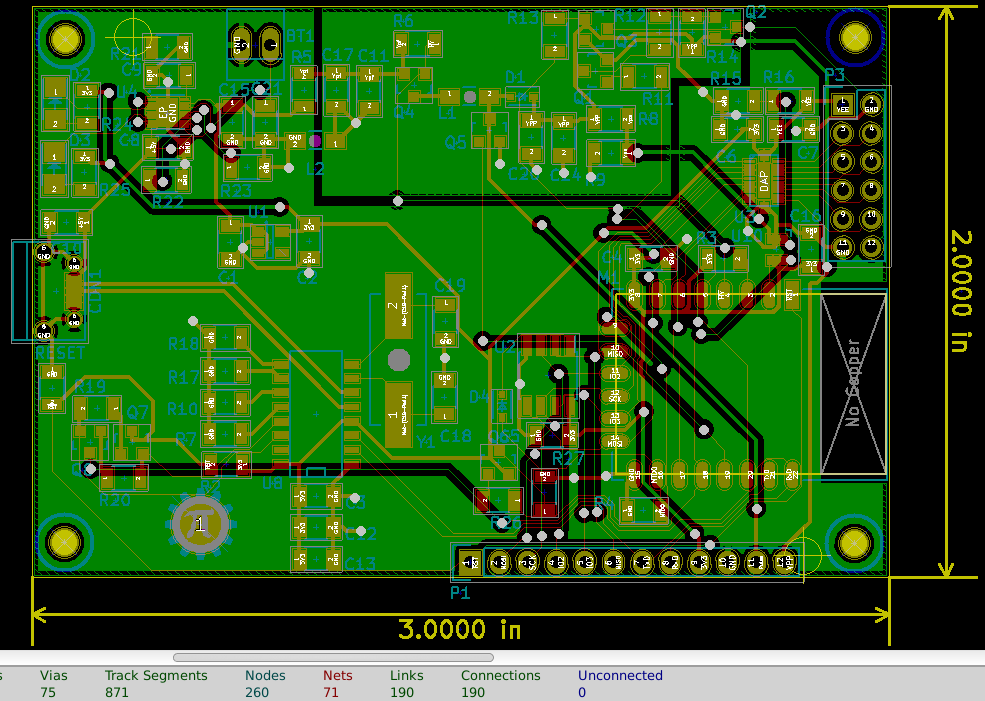

This left me with a bunch of parts all jumbled together. I started by spreading them out so I could see their ratsnest better. Once I saw how much components needed to be moved around, I ripped up all traces as well as the ground plane. This gives me the freedom to re-arrange the board more efficiently. My strategy was to start at each end of the board and work to the middle.

Looking at the design, the switch for upload takes up a lot of space and is not needed. I went back into the schematic and removed the upload switch. This required that I generate a new netlist and read it into PCBnew.

I left the USB connector where it was, put the Lithium cell in the NW corner, the Reset circuit in the SW corner, the wifi module in the SE corner, The test header along the south edge, the target connector on the NE corner and the high voltage circuit along the north edge.

I routed the board using the interactive router. I then added my logo on to the board. I want to edit my logo a little bit, I may change that before I send the files off to fabrication.

The kicad files are on www.github.com, use the link just below my logo to download them.

Do you have any comments, would you do something differently, can you see a better placement of parts?